I. Core Advantages of OPPAIR Oil-Free Scroll Compressors

1. Zero-Contamination Compressed Air

Oil-free scroll compressors utilize scroll technology, eliminating the need for lubricating oil in the compression process. The air purity achieved meets ISO 8573-1 Class 0 (International Organization for Standardization certification), completely eliminating oil contamination. For example, in medical applications (such as ventilators and dental equipment) and food processing, this feature ensures product safety and prevents bacterial growth and equipment failure caused by oil contamination.

2. High Efficiency and Energy Saving, Low Operating Costs

Compared to traditional piston air compressors, oil-free scroll compressors typically offer a 20%-30% higher Energy Efficiency Ratio (COP). For example, a 7.5kW model operating for 8,000 hours per year can save approximately 12,000 yuan in electricity costs (based on the industrial electricity price of 0.8 yuan/kWh). Its scroll structure reduces mechanical friction, resulting in minimal energy loss, making it ideal for 24-hour continuous operation.

3. Low Noise and Vibration

Operating noise levels are generally below 60 decibels (measured at a distance of 1 meter), equivalent to the volume of a normal conversation. For example, OPPAIR scroll compressors are only 58 decibels, significantly lower than the 75 decibels of screw compressors. This feature allows them to be installed directly in offices or laboratories without the need for additional soundproofing.

II. Extended Advantages and Industry Compatibility

1. Simple Maintenance and Long Life

The oil-free design eliminates the cost of regular oil filter and oil separator replacements, extending maintenance intervals to 4,000-5,000 hours (compared to 2,000 hours for conventional compressors). Core components such as the scroll have a lifespan of over 100,000 hours (data source: Compressed Air and Gas Handbook), significantly reducing the risk of downtime.

2. Compact and Lightweight, Saving Space

For example, a 55kW oil-free scroll compressor occupies less than 1 square meter, making it suitable for space-constrained factories or mobile applications.

3. Wide Temperature Adaptability

It can operate stably in environments ranging from -10°C to 45°C (some industrial models extend this range to -20°C), with exhaust temperatures below 40°C, preventing high temperatures from damaging back-end equipment.

III. Practical Considerations

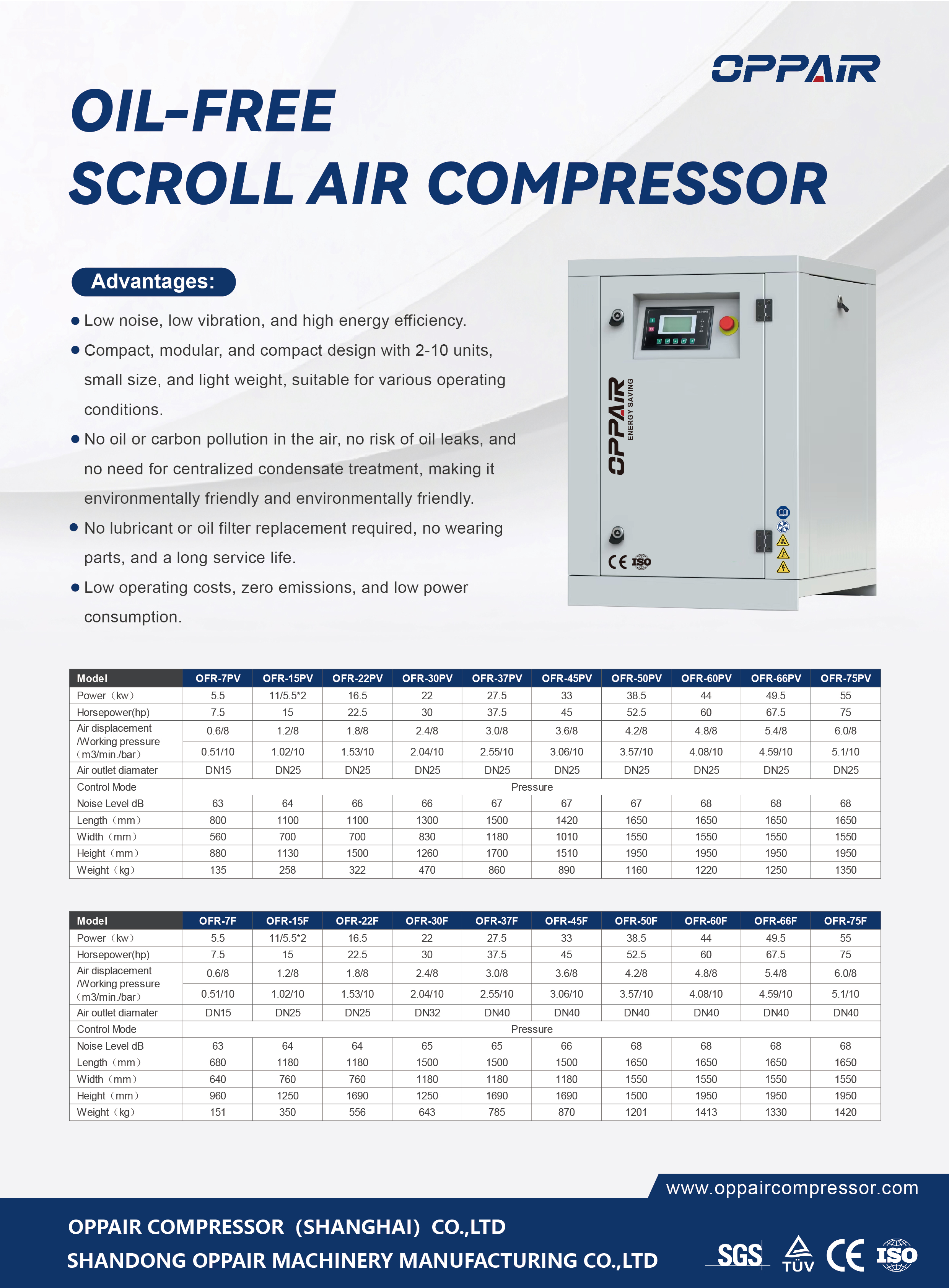

Despite their significant advantages, the power output of oil-free scroll air compressors typically does not exceed 75kW (due to the physical limitations of the scroll structure), making them suitable for small to medium flow requirements (0.5-20 m³/min). Users should select a model based on actual air usage to avoid overloading. Furthermore, while the initial purchase cost is slightly higher (15%-20% more expensive than oil-lubricated models of the same power), the long-term energy savings more than offset the price difference.

IV. Applications in the Medical Industry

In the medical industry, air compressors are not only power generators but are also directly related to the stable operation of medical equipment and the health and safety of patients. Compared to traditional oil-lubricated air compressors, oil-free scroll air compressors are becoming the preferred choice for hospitals and medical device manufacturers due to their cleanliness, stability, and efficiency.

1. Oil-free design ensures air cleanliness.

Medical equipment, such as ventilators, dental equipment, and operating room air supply, requires extremely high air quality. Any oil contamination can affect treatment effectiveness and even endanger patient health.

Oil-free scroll air compressors feature a completely oil-free design, delivering air cleanliness that meets medical industry standards, ensuring safe and reliable equipment operation.

2. Low-noise operation, suitable for medical environments.

Hospitals have strict requirements for equipment noise, especially in consulting rooms, operating rooms, and wards. Oil-free scroll air compressors offer a compact design, smooth operation, and lower noise levels than traditional models, creating a quiet and comfortable medical environment for medical staff and patients.

3. Stable operation, ensuring continuous air supply.

Medical equipment requires long-term, stable compressed air support. Oil-free scroll air compressors utilize a high-precision scroll design to reduce mechanical friction, resulting in a long operating life. They maintain stable air supply even under high loads, preventing equipment downtime from disrupting medical work.

4. Energy-saving and high-efficiency, reducing operating costs.

Energy consumption is a significant cost in the daily operations of medical institutions. Oil-free scroll air compressors achieve efficient energy conversion and lower energy consumption through optimized structure and control systems, helping hospitals reduce operating costs while ensuring stable air supply.

5. Wide Application Scenarios

Applications of oil-free scroll air compressors in the medical industry include:

Hospital operating room air supply

Ventilator and anesthesia machine air supply

Dental clinic air support

Medical testing instrument air supply

Laboratory oil-free air supply requirements

Conclusion

For the medical industry, selecting the right air compressor is not just a matter of equipment procurement; it is also a guarantee of patient safety and medical quality. With its advantages of clean air, low noise, stable operation, and energy-saving efficiency, OPPAIR oil-free scroll air compressors have been widely used in many medical institutions across the country, making them a trusted brand of energy-saving air compressors in the medical industry.

OPPAIR is looking for global agents, welcome to contact us for inquiries

WeChat/ WhatsApp: +86 14768192555

#Electric Rotary Screw air Compressor #Screw Air Compressor With Air Dryer #High Pressure Low Noise Two Stage Air Compressor Screw#All in one screw air compressors#Skid mounted laser cutting screw air compressor#oil cooling screw air compressor#OPPAIR#Nitrogen Generator#oil free scroll air compressor#oil free water lubricating screw air compressor#oil free dryer screw air compressor

Post time: Sep-17-2025