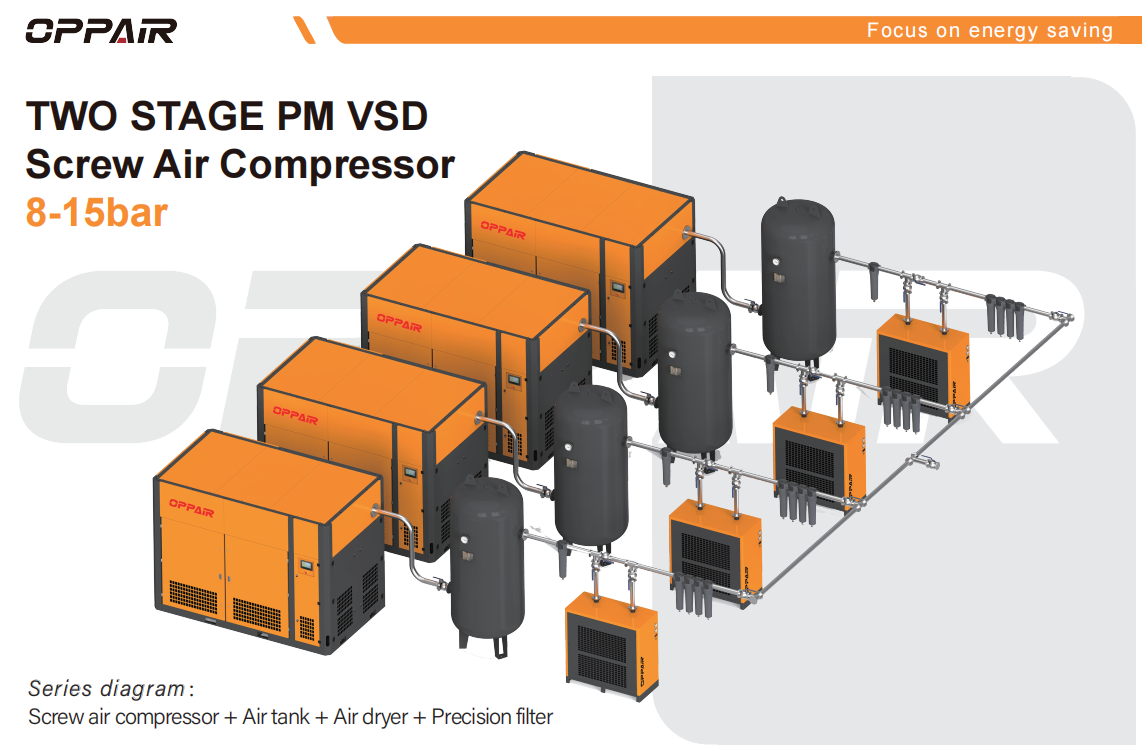

The use and demand of two-stage screw air compressors are increasing. Why are two-stage screw air compress machines so popular? What are its advantages? will introduce you to the advantages of two-stage compression energy-saving technology of screw air compressors.

1. Reduce the compression ratio

The two-stage compression screw air compressor changes the process of compressed air from single-stage compression to two-stage compression through technological innovation. Such compression technology can reduce the “compression ratio” of each stage of compression, greatly reduce the backflow leakage, greatly increase the output flow of the machine, and improve the volume efficiency of compressed air, thereby reducing the load of bearings and gears inside the machine. In this way, it can reduce the power used by the machine during compression, reduce the wear of parts, and extend the life of the screw air compressor accordingly.

In the past, the single-stage compression technology, in the process of compressing air, because the compression ratio is high, the resistance to work is large, resulting in a lot of useless work in the process of compressing air. After adopting the two-stage compression technology, because the compression ratio is reduced, a lot of useless work is reduced, and a lot of power usage is reduced.

2. Reduce the gas temperature

During the process of gas compression by the PM VSD screw air compressor , the gas will produce friction with the moving parts inside the machine when it is compressed by the rotary air compressor. Because of the friction, the temperature of the gas will rise. As the saying goes, heat expands and cold contracts, the gas will inevitably expand, and this part of the gas will also produce corresponding pressure, which will increase the compression ratio. The screw air compressor will increase the power to compress the air, which will cause power loss. Therefore, to reduce the power loss, the gas must be cooled.

The two-stage compression screw air compressor is equipped with a coolant spray curtain. After the gas passes through the first stage of compression, the coolant spray curtain inside the compressor will spray coolant on it, and the temperature of the gas will be reduced. After the cooling effect is produced, it will enter the second stage of compression. The coolant spray device greatly reduces the power loss, not only reduces the temperature of the gas, but also reduces the temperature of the entire compression system, and also saves the installation of the cooler, reducing the production cost of the compressor. Because the coolant sprayed by the coolant spray device is in a mist form, it also reduces the volatilization of the coolant, which can keep the oil coolant for a long time.

The two-stage screw air compressor has a simple structure, easy assembly, high working efficiency, and the key is that it also has the advantage of energy saving, which is a major technological achievement in the field of energy saving.

3. Large diameter screw has low power loss

The larger the diameter of the screw air compressor, the higher the linear speed. Under the same working conditions, the higher the volumetric efficiency and the greater the flow rate. The two-stage screw air compressor uses an ultra-large diameter screw, which is much larger than the diameter of the twin-screw air compressor. That is to say, at the same speed, the flow rate of the two-stage screw air compressor is much larger than that of the twin-screw air compressor. On the contrary, with the same flow rate, the speed of the two-stage screw air compressor will be much lower than that of the twin-screw air compressor, and the power loss will be smaller. The loss of machine components will also be reduced, thereby extending the life of the machine, ensuring the continuous and reliable operation of the compressor, and reducing the production and operation costs of the enterprise.

Because the screw diameter of the two-stage screw compressor is large and the speed is low under the same working conditions, the noise generated by the machine is much smaller. It is also more convenient to repair and maintain.

4. Scientific host design

The two-stage screw air compressor combines the first-stage compression rotor and the second-stage compression rotor in one casing. The rotors of each stage are directly driven by gears, so that the rotors of each stage can obtain the most ideal linear speed, and the compression efficiency is improved.

5. Strong economic benefits

The air compressor is a machine with high energy consumption. For enterprises using air compressors, in addition to the requirements for the efficiency and quality of the machine, the most concerned issue may be energy saving. Energy-saving technology directly affects the operating costs and economic benefits of the enterprise. The operating cost of the two-stage screw air compressor is much lower than that of the screw air compressor using single-stage technology. It saves more electricity than the single-stage compression screw air compressor, has higher efficiency than the single-stage compression screw air compressor, and has lower noise than the single-stage screw air compressor. Therefore, today’s enterprises should still choose two-stage screw compressors.

OPPAIR is looking for global agents, welcome to contact us for inquiries: WhatsApp: +86 14768192555

#Electric Rotary Screw air Compressor #Screw Air Compressor With Air Dryer #High Pressure Low Noise Two Stage Air Compressor Screw#All in one screw air compressors#Skid mounted laser cutting screw air compressor#oil cooling screw air compressor

Post time: Jun-26-2025