How to replace the oil filter?

How to replace the air filter?

How to change the oil in the air compressor?

How to replace the oil-air separator?

How to adjust controller parameters after maintenance?

In order to avoid premature wear of the screw compressor and blockage of the fine filter element in the oil-air separator, the filter element usually needs to be cleaned or replaced.

Maintenance time is: 2000-3000 hours (including the first maintenance)

once; In dusty areas, the replacement time should be shortened.

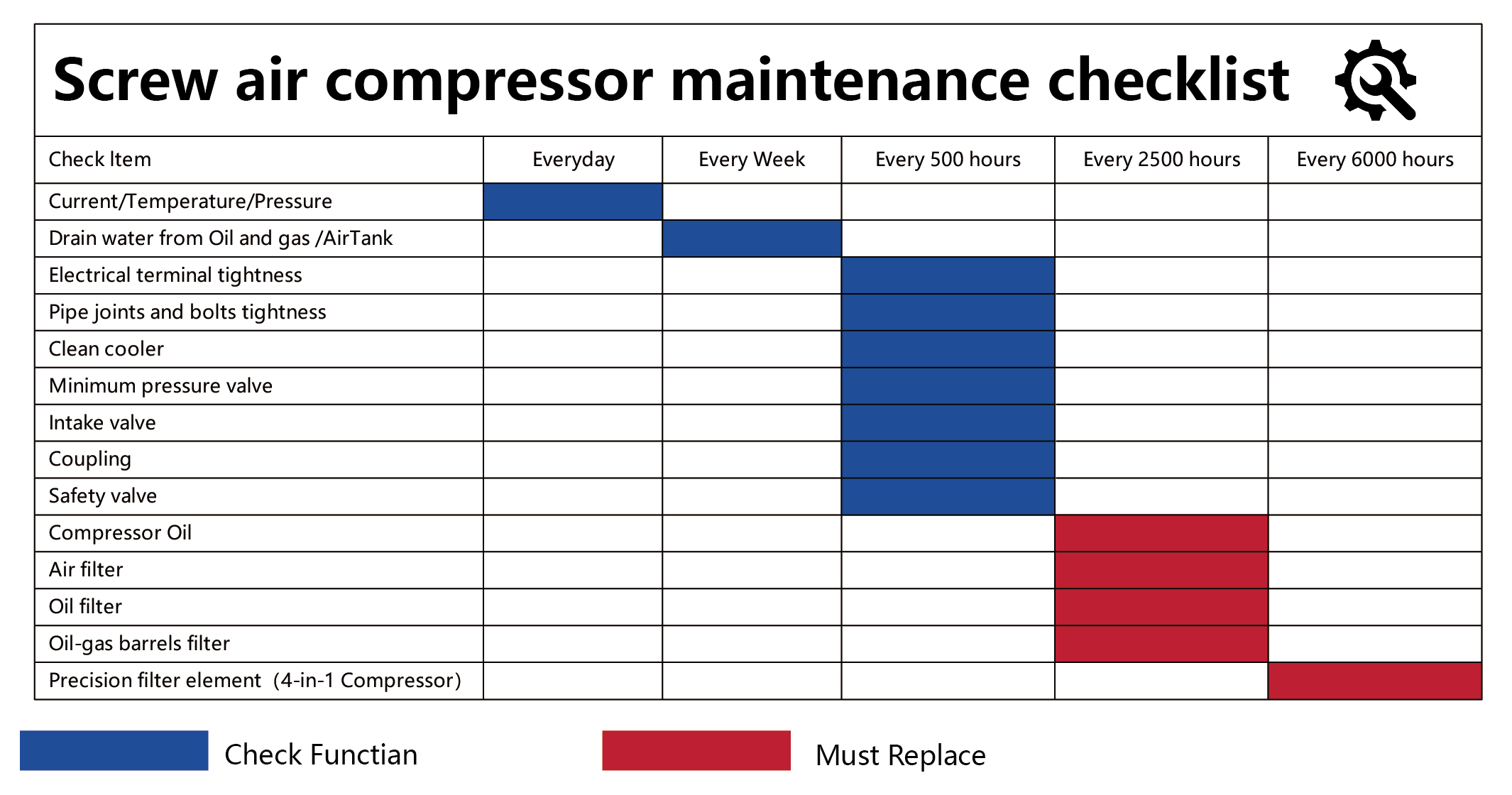

You can refer to our maintenance schedule below:

Note: When replacing the filter, you must ensure that the equipment is not running. During installation, you must check whether there is static electricity in each component. The installation must be tight to avoid accidents.

Let's take a look at the replacement method of the OPPAIR air compressor filter.

1.Replace the air filter

First, the dust on the surface of the filter should be removed to prevent contamination of the equipment during the replacement process, thereby affecting the quality of air production. When replacing, first knock, and use dry air to remove dust in the opposite direction. This is the most basic inspection of the air filter, so as to check the problems caused by the filter, and then decide whether to replace and repair.

You can refer to the video we uploaded on YouTube:

2.When maintaining a screw air compressor, how to replace the oil filter and the air compressor oil?

Before adding new lubricant, you need to drain all the previous lubricant from the oil and gas barrel and the air end. (This is very important!!)

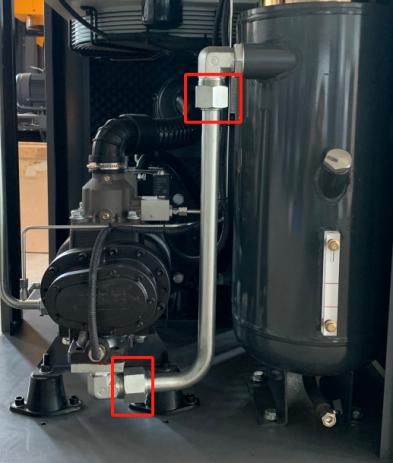

The lubricant in the oil and gas barrel is drained from here.

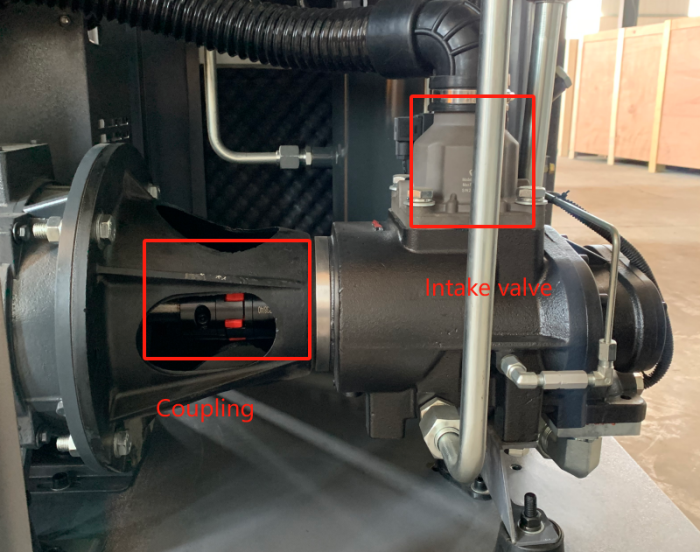

To drain the oil in the air end, you need to remove the screws on this connecting pipe, turn the coupling in the direction of the arrow, and press the air inlet valve.

(1) After drain all the oil, add some lubricating oil to the oil and gas barrel. See the oil level gauge for the specific amount of oil. When the air compressor is not running, the oil level should be kept above the two red lines. (When running, it should be kept between the two red lines)

(2)Press and hold the air inlet valve, fill the air end with oil, and then stop when the oil is full. This is adding the oil into the air end.

(3)Open a new oil filter and add some lubricating oil to it.

(4) Apply a small amount of lubricating oil, which will seal the oil filter.

(5) Finally, tighten the oil filter.

The reference video for replacing the oil filter and lubricating oil is as follows:

The reference video for replacing the oil filter and lubricating oil is as follows:

Details to note:

(1)The maintenance of the screw air compressor is: 2000-3000 hours (including the first maintenance)

(2)When maintaining an air compressor, besides replacing the air compressor oil, what else needs to be replaced? Air filter, oil filter and oil separator

(3)For pressures of 16 bar/20 bar and above, use No. 68 oil; for pressures below 16 bar, use No. 46 oil. It is recommended to use Shell fully synthetic or semi-synthetic air compressor oil.

2.Replace the oil-air separator

When replacing, it should start from various small pipelines. After dismantling the copper pipe and cover plate, remove the filter element, and then clean the shell in detail. After replacing the new filter element, install it according to the opposite direction of removal.

Specific steps are as follows:

(1) Remove the pipe connected to the minimum pressure valve.

(2) Loosen the nut under the minimum pressure valve and remove the corresponding pipe.

(3) Loosen the pipe and screws on the oil and air barrel.

(4) Take out the old oil separator and put in the new oil separator. (To be placed in the center)

(5) Install the minimum pressure valve and corresponding screws. (Tighten the screws on the opposite side first)

(6) Install the corresponding pipes.

(7) Install the two oil pipes and tighten the screws.

(8) After ensuring that all pipes are tightened, the oil separator has been replaced.

You can refer to the video we uploaded on YouTube:

The amount of lubricating oil that needs to be added for maintenance needs to be based on the power, refer to the figure below:

|

When the air compressor has no oil, the amount of air compressor oil that needs to be added: |

|||||||||

| Power |

7.5kw |

11kw |

15kw |

22kw |

30kw |

37kw |

45kw |

55kw |

75kw |

| Lubricating oil |

5L |

10L |

16L |

25L |

45L |

||||

Note: If the oil in the air compressor is not drained cleanly when replacing the air compressor oil, you need to reduce the amount appropriately when adding the air compressor oil.

3. Controller Parameter adjustment after maintenance

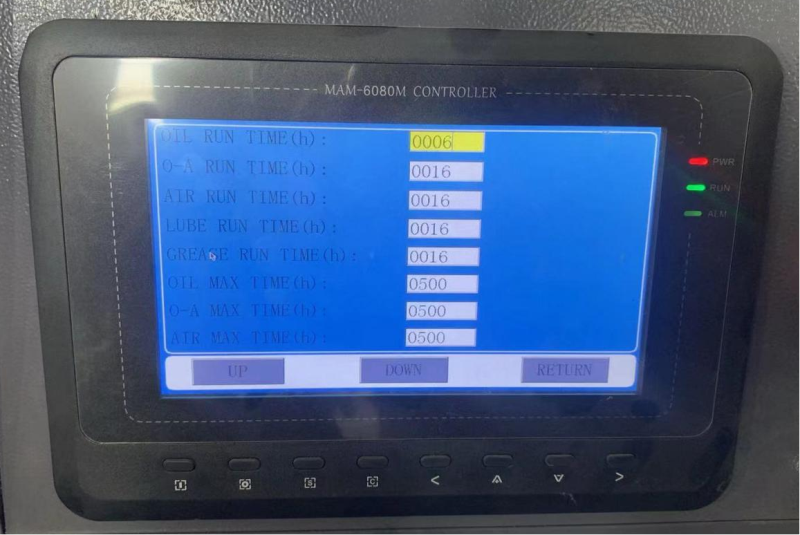

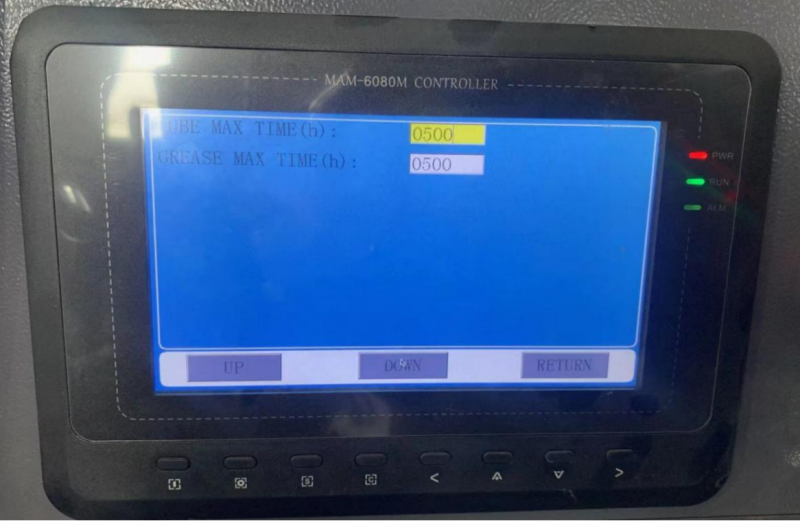

After each maintenance, we need to adjust the parameters on the controller. Take the controller MAM6080 as an example:

After maintenance, we need to adjust the run time of the first few items to 0, and the Max time of the last few items to 2500.

If you need more videos about the use and operation of air compressors, please follow our Youtube and search for OPPAIR COMPRESSOR.

https://www.youtube.com/@oppaircompressor1389

OPPAIR is looking for global agents, welcome to contact us for inquiries: WhatsApp: +86 14768192555

#Electric Rotary Screw air Compressor #Screw Air Compressor With Air Dryer #High Pressure Low Noise Two Stage Air Compressor Screw#All in one screw air compressors#Skid mounted laser cutting screw air compressor

Post time: Jul-05-2025