16. What is pressure dew point?

Answer: After the moist air is compressed, the density of water vapor increases and the temperature also rises. When the compressed air is cooled, the relative humidity will increase. When the temperature continues to drop to 100% relative humidity, water droplets will be precipitated from the compressed air. The temperature at this time is the “pressure dew point” of the compressed air.

17. What is the relationship between pressure dew point and normal pressure dew point?

Answer: The corresponding relationship between the pressure dew point and the normal pressure dew point is related to the compression ratio. Under the same pressure dew point, the larger the compression ratio, the lower the corresponding normal pressure dew point. For example: when the dew point of compressed air pressure of 0.7MPa is 2°C, it is equivalent to -23°C at normal pressure. When the pressure increases to 1.0MPa, and the same pressure dew point is 2°C, the corresponding normal pressure dew point drops to -28°C.

18. What instrument is used to measure the dew point of compressed air?

Answer: Although the unit of pressure dew point is Celsius (°C), its connotation is the water content of compressed air. Therefore, measuring the dew point is actually measuring the moisture content of the air. There are many instruments for measuring the dew point of compressed air, such as “mirror dew point instrument” with nitrogen, ether, etc. as cold source, “electrolytic hygrometer” with phosphorus pentoxide, lithium chloride, etc. as electrolyte, etc. At present, special gas dew point meters are widely used in the industry to measure the dew point of compressed air, such as the British SHAW dew point meter, which can measure up to -80°C.

19. What should be paid attention to when measuring the dew point of compressed air with a dew point meter?

Answer: Use a dew point meter to measure the air dew point, especially when the water content of the measured air is extremely low, the operation must be very careful and patient. Gas sampling equipment and connecting pipelines must be dry (at least drier than the gas to be measured), the pipeline connections should be completely sealed, the gas flow rate should be selected according to regulations, and a long enough pretreatment time is required. If you are careful, there will be big errors. Practice has proved that when the “moisture analyzer” using phosphorus pentoxide as the electrolyte is used to measure the pressure dew point of the compressed air treated by the cold dryer, the error is very large. This is due to secondary electrolysis generated by the compressed air during the test, making the reading higher than it actually is. Therefore, this type of instrument should not be used when measuring the dew point of compressed air handled by a refrigerated dryer.

20. Where should the pressure dew point of compressed air be measured in the dryer?

Answer: Use a dew point meter to measure the pressure dew point of compressed air. The sampling point should be placed in the exhaust pipe of the dryer, and the sample gas should not contain liquid water droplets. There are errors in the dew points measured at other sampling points.

21. Can the evaporation temperature be used instead of the pressure dew point?

Answer: In the cold dryer, the reading of the evaporation temperature (evaporation pressure) cannot be used to replace the pressure dew point of the compressed air. This is because in the evaporator with limited heat exchange area, there is a non-negligible temperature difference between the compressed air and the refrigerant evaporation temperature during the heat exchange process (sometimes up to 4~6°C); the temperature to which the compressed air can be cooled is always higher than that of the refrigerant. Evaporation temperature is high. The separation efficiency of the “gas-water separator” between the evaporator and the pre-cooler cannot be 100%. There will always be a part of the inexhaustible fine water droplets that will enter the pre-cooler with the air flow and “secondarily evaporate” there. It is reduced to water vapor, which increases the water content of the compressed air and raises the dew point. Therefore, in this case, the measured refrigerant evaporation temperature is always lower than the actual pressure dew point of the compressed air.

22. Under what circumstances can the method of measuring temperature be used instead of pressure dew point?

Answer: The steps of intermittently sampling and measuring air pressure dew point with SHAW dew point meter at industrial sites are quite cumbersome, and the test results are often affected by incomplete test conditions. Therefore, in occasions where the requirements are not very strict, a thermometer is often used to approximate the pressure dew point of compressed air.

The theoretical basis for measuring the pressure dew point of compressed air with a thermometer is: if the compressed air that enters the precooler through the gas-water separator after being forced to cool by the evaporator, the condensed water carried in it is completely separated in the gas-water separator, then at this time The measured compressed air temperature is its pressure dew point. Although in fact the separation efficiency of the gas-water separator cannot reach 100%, but under the condition that the condensed water of the pre-cooler and the evaporator is well discharged, the condensed water that enters the gas-water separator and needs to be removed by the gas-water separator only accounts for A very small fraction of the total condensate volume. Therefore, the error in measuring the pressure dew point by this method is not very large.

When using this method to measure the pressure dew point of compressed air, the temperature measuring point should be selected at the end of the evaporator of the cold dryer or in the gas-water separator, because the temperature of the compressed air is the lowest at this point.

23. What are the compressed air drying methods?

Answer: Compressed air can remove water vapor in it by pressurization, cooling, adsorption and other methods, and liquid water can be removed by heating, filtration, mechanical separation and other methods.

The refrigerated dryer is a device that cools down the compressed air to remove the water vapor contained in it and obtain relatively dry compressed air. The rear cooler of the air compressor also uses cooling to remove the water vapor contained in it. Adsorption dryers use the principle of adsorption to remove water vapor contained in compressed air.

24. What is compressed air? What are the characteristics?

Answer: Air is compressible. The air after the air compressor does mechanical work to reduce its volume and increase its pressure is called compressed air.

Compressed air is an important source of power. Compared with other energy sources, it has the following obvious characteristics: clear and transparent, easy to transport, no special harmful properties, and no pollution or low pollution, low temperature, no fire hazard, no fear of Overload, able to work in many adverse environments, easy to obtain, inexhaustible.

25. What impurities are contained in compressed air?

Answer: The compressed air discharged from the air compressor contains many impurities: ①Water, including water mist, water vapor, condensed water; ②Oil, including oil stains, oil vapor; ③Various solid substances, such as rust mud, metal powder, rubber Fines, tar particles, filter materials, fines of sealing materials, etc., in addition to a variety of harmful chemical odor substances.

26. What is an air source system? What parts does it consist of?

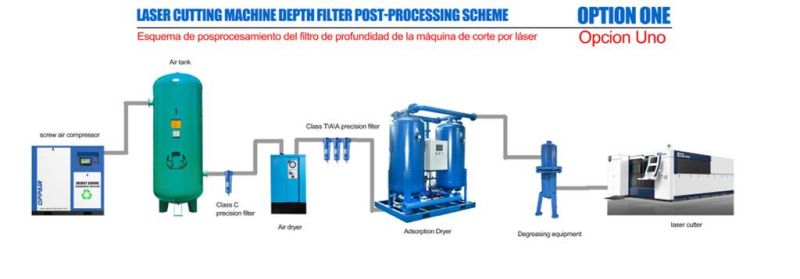

Answer: The system composed of equipment that generates, processes and stores compressed air is called an air source system. A typical air source system usually consists of the following parts: air compressor, rear cooler,Filters (including pre-filters, oil-water separators, pipeline filters, oil removal filters, deodorization filters, sterilization filters, etc.), pressure-stabilized gas storage tanks, dryers (refrigerated or adsorption) , Automatic drainage and sewage discharger, gas pipeline, pipeline valve parts, instruments, etc. The above equipment is combined into a complete gas source system according to the different needs of the process.

27. What are the hazards of impurities in compressed air?

Answer: The compressed air output from the air compressor contains a lot of harmful impurities, the main impurities are solid particles, moisture and oil in the air.

Vaporized lubricating oil will form an organic acid to corrode equipment, deteriorate rubber, plastic, and sealing materials, block small holes, cause valves to malfunction, and pollute products.

The saturated moisture in the compressed air will condense into water under certain conditions and accumulate in some parts of the system. These moistures have a rusting effect on components and pipelines, causing moving parts to be stuck or worn, causing pneumatic components to malfunction and air leakage; in cold regions, moisture freezing will cause pipelines to freeze or crack.

Impurities such as dust in the compressed air will wear the relative moving surfaces in the cylinder, air motor and air reversing valve, reducing the service life of the system.

Post time: Jul-17-2023