Screw air compressors have become the leader in today's air compressor market due to their high efficiency, strong reliability and easy maintenance. However, to achieve optimal performance, all components of an air compressor need to work in harmony. Among them, the exhaust port of the screw air compressor is equipped with a key but delicate part, namely the oil return check valve.

So, what is the working principle and function of this component?

1. What does the oil return check valve consist of?

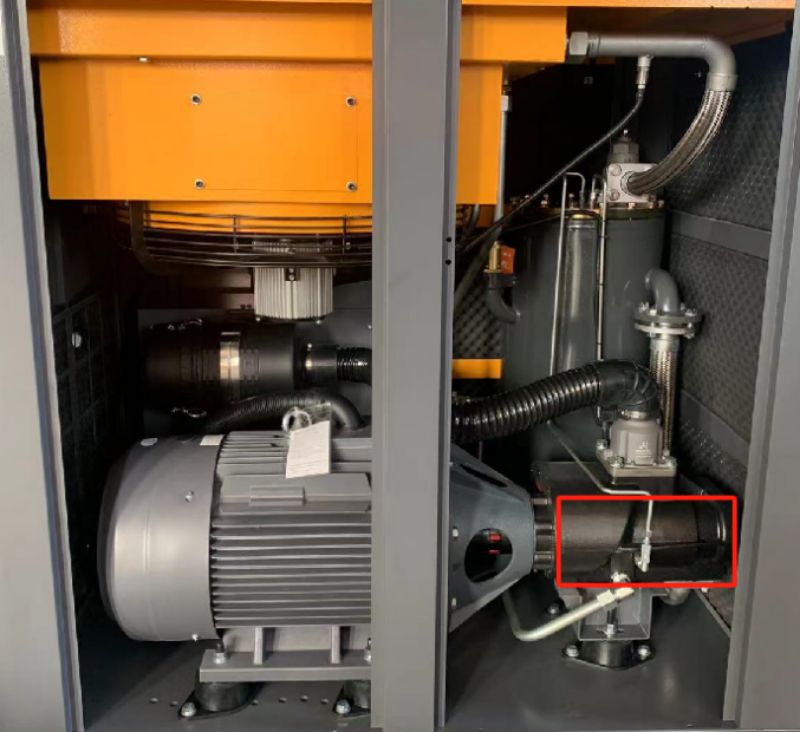

The oil return check valve consists of a valve body, steel balls, steel ball seats and springs.

2.How does the oil return check valve work?

The oil and air mixture of the air compressor air end is initially separated in the oil and air tank the oil and air mixture will sink to the bottom of the oil tank through centrifugal force.

Then, driven by the internal pressure, the screw air compressor guides most of the oil back to the main engine for the next round of lubrication cycle.

The remaining compressed air containing a small amount of oil is separated again through the oil and air separator.

At this time, the lubricating oil separated by the separator will fall to the bottom of the separator.

3.The oil return check valve exists in the air end, and how to replace the air end?

You can refer to the video in the link below:

https://youtu.be/2MBU-qSt0A8?si=09YLR789OwrA2EvZ

In order to prevent this part of the oil from being taken away by the compressed air, the designer specially inserted an oil pipe at the bottom of the oil and air separator, and installed a one-way valve on the pipe, which is the so-called oil return check valve.

The main function of the oil return check valve is to only allow the air from the compressor to enter the air tank and prevent the air in the air tank from returning to the compressor. If the oil return check valve fails, when the air compressor is shut down, the air in the air tank will be discharged through the pressure relief valve, causing the compressor to start repeatedly.

Every part of the air compressor plays a vital role. Only when all parts work together can the air compressor achieve its maximum performance. Therefore, we must understand the functions of the main components of the air compressor and do routine care and maintenance to prevent failures.

So, how should the oil return check valve be selected and installed?

When selecting and installing an oil return check valve, the following factors need to be considered:

1.Its flow capacity: It is necessary to select the appropriate oil return check valve model according to the working flow of the air compressor.

2.Physical size: The oil return check valve should be the same size as the water tank return line to facilitate installation and maintenance.

3.Anti-clogging performance: Consider the impact of sediments and impurities that may be generated during the oil return process on the oil return check valve, and select a valve with good anti-clogging performance.

4.Adaptability: The oil return check valve should be compatible with other air compressor pipelines and accessories.

In short, the oil return check valve plays a very important role in the operation of a single-screw air compressor. Proper selection and installation can improve the working efficiency and performance of the compressor and ensure the long-term stable operation of the air compressor.

Post time: Nov-11-2023