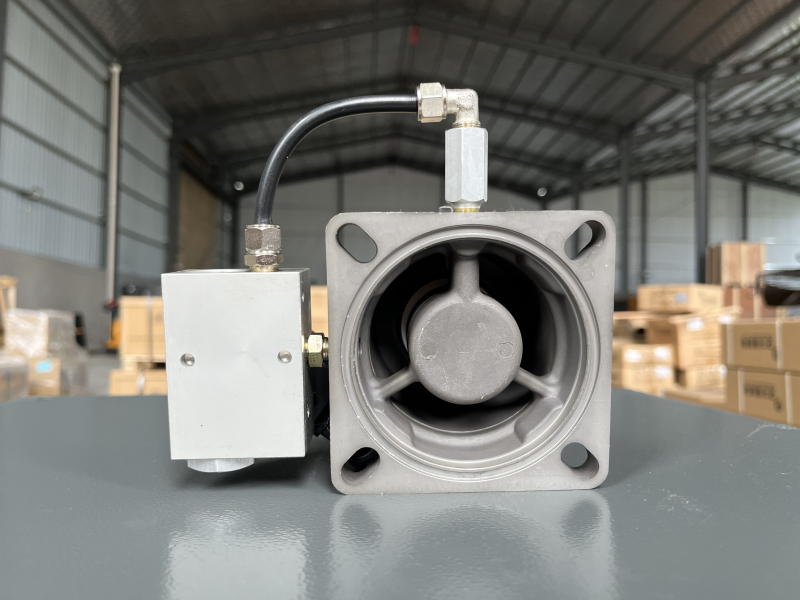

The intake valve is an important part of the screw air compressor system. However, when the intake valve is used on a permanent magnet variable frequency air compressor, there may be vibration of the intake valve. When the motor is running at the lowest frequency, the check plate will vibrate, resulting in intake noise. So, what is the reason for the vibration of the intake valve of the permanent magnet variable frequency air compressor?

Reasons for the vibration of the intake valve of the permanent magnet variable frequency air compressor:

The main reason for this phenomenon is the spring under the valve plate of the intake valve. When the intake air volume is small, the air flow is unstable and the spring force is relatively large, which will cause the valve plate to vibrate. After replacing the spring, the spring force is small, which can basically solve the above problems.

In principle, when the intake valve is activated, the intake valve of the air compressor is closed, and the motor drives the main engine to idle. When the valve is loaded, the intake valve opens. Usually, a gas pipe larger than 5mm is extracted from the top cover of the oil-gas separator, and the intake valve is controlled by the switch of the solenoid valve (usually the solenoid valve is turned on). When the solenoid valve is energized, the intake valve without compressed air is automatically inhaled and opened, the intake valve is loaded, and the air compressor starts to inflate. When the solenoid valve is de-energized, compressed air enters the intake valve, the air pressure lifts the piston, the intake valve closes, and the exhaust valve opens.

The air pressure is divided into two ways, one way into the exhaust valve and the other way into the compressor. The exhaust valve has a fitting to adjust the exhaust size to control the pressure in the separator barrel. The pressure can generally be adjusted to 3 kg, the pressure increases by turning clockwise, and the pressure decreases by counterclockwise, and the adjusted nut is fixed.

Loading valve air volume adjustment method, when the user’s natural gas consumption is less than the unit’s rated exhaust volume, the pressure in the user’s pipe network system will rise. When the pressure reaches the set value of the unloading pressure, the solenoid valve is powered off, the air source is cut off, and the control enters the combined valve of the intake controller. The piston closes under spring force and the exhaust valve opens. The compressed air in the oil-gas separator returns to the air inlet, and the pressure drops to a certain value.

At this time, the minimum pressure valve is closed, the user pipe network is separated from the unit, and the unit is in the no-load operation state. As the pressure of the user’s pipe network gradually drops to the set value of the load pressure, the solenoid valve gets power and is connected to the control air source of the combined valve in the intake controller. Under the action of this pressure, the piston opens against the force of the spring, at the same time the exhaust valve closes, and the unit resumes loading operation.

The above is the reason for the vibration of the intake valve of the permanent magnet variable frequency air compressor. The intake valve works in conjunction with the solenoid valve, pressure sensor, and microcomputer controller to control the switch of the compressor intake port. When the unit starts, The intake valve is closed, which plays the role of air intake throttling adjustment, so that the compressor starts at light load; when the air compressor is running at full load, the intake valve is fully opened; when the air compressor is running at no load, the intake valve is closed and the oil and gas are separated The pressure in the separator is released to 0.25-0.3MPa to ensure the oil supply pressure of the main engine; when the machine is shut down, the intake valve is closed to prevent the gas in the oil-gas separator from flowing back, causing the rotor to reverse and the oil injection at the intake port to occur.

Post time: Aug-01-2023