What are the steps to start a screw air compressor? How to choose a circuit breaker for an air compressor? How to connect the power supply? How to judge the oil level of screw air compressor? What should we pay attention to when operating a screw air compressor? How to shut down the air compressor? What is the password for OPPAIR air compressor?

1.What should be done before starting the screw air compressor? What should you do before starting the screw air compressor? Screw air compressor start up steps.

(1)Check whether there are some objects in the air compressor. During transportation, in order to save transportation space, our company usually puts the maintenance filter element and accessories in the compressor. After the customer receives the compressor, should first take out these spare parts.

(2)Select the correct circuit breaker and wires, confirm that the power supply is connected correctly and the indicator light is on.

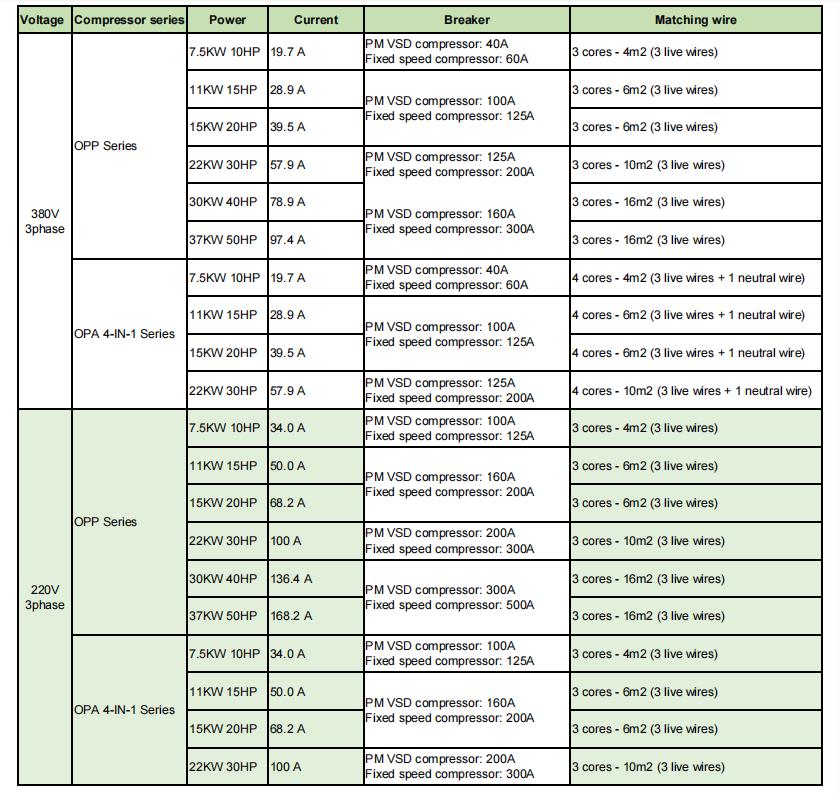

① How to choose the correct circuit breaker and wires?

② How to connect the power supply?

You can refer to these two videos we uploaded on YouTube:

What should do if the controller displays "phase sequence error" or "motor unbalanced" after connecting to the power supply?

Cut off the power, swap any two fire wires, then reconnect the power supply and restart to return to normal.

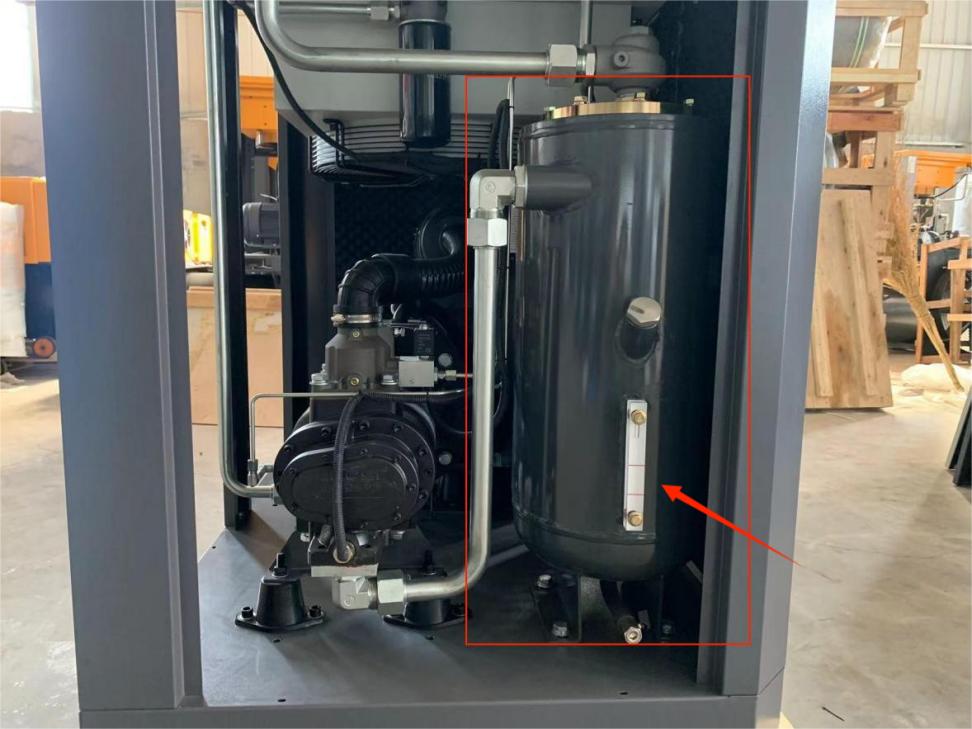

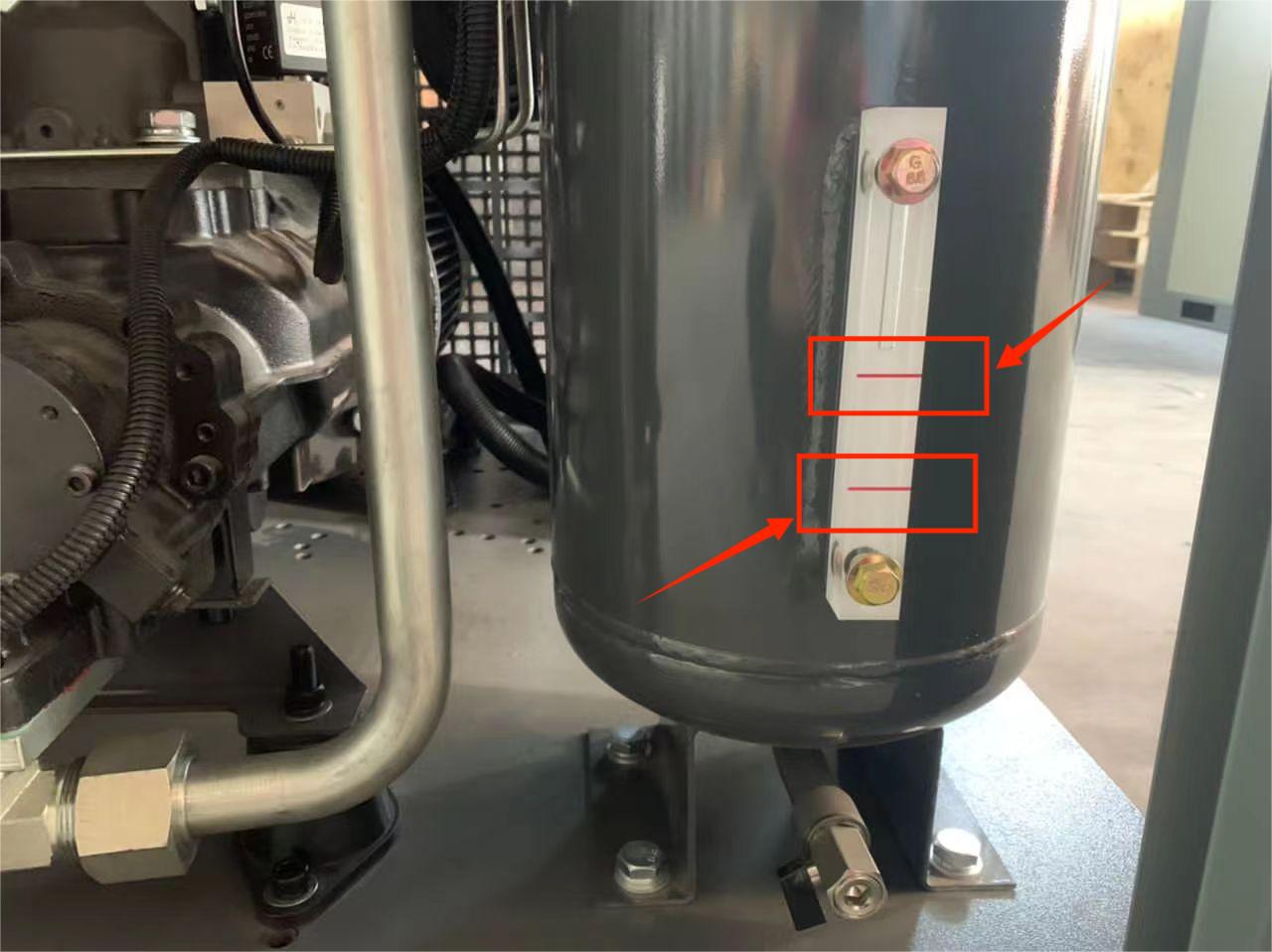

(3)Check the air compressor oil level. Before starting, the air compressor oil level should be higher than the red warning line above. After starting, the air compressor oil level should be between the two red warning lines.

Usually, before OPPAIR shipped, each machine will make strict testing, air compressor oil has been added, and customers can directly connect to the power supply for use. In order to avoid accidents, it is necessary to check whether the lack of air compressor oil before operation.

(4)Check if there any air, oil or water leaks at each connection part.

(5)Press the "Start" button. After starting, the "Start" indicator light should light up and the compressor will start running.

(6)The compressor automatically loads in about 2 seconds, the intake valve opens, and the exhaust pressure pointer of the oil and gas barrel rises.

(7)After starting the loading, check whether the oil level is within the normal range (before starting, the air compressor oil should be higher than the red warning line above, and after starting, the air compressor oil level should be between the two red warning lines.) .

(8)Check if there any air, oil or water leaks at each connection part.

2.What should we pay attention to when operating a screw air compressor? What should you pay attention to when using an air compressor? Air compressor user guide.

(1)When there are abnormal noises or abnormal vibrations during operation, press the emergency stop button immediately.

(2)The bolts of the pipelines cannot be loosened because there is pressure in the running pipelines.

(3)During running, if the oil level of the oil and gas barrel is found to be lower than the red warning line, stop the machine immediately, wait for about 30 minutes for the air compressor to cool down, then replenish the air compressor oil, then restart.

(4)Oil and gas barrels should be drained once a week. If the using air consumption is small, the water in the oil and gas barrel needs to be discharged every day until the air compressor oil appears. If the water in the oil and gas barrel is not discharged regularly, it will easily cause the air end to rust and the air compressor to be damaged.

(5)The air compressor must run for more than 1 hour at one time and cannot be turned on and off frequently in a short period of time.

(6)Before the air compressor leaves the factory, OPPAIR has adjusted the parameters. Customers do not need to modify the parameters themselves and can directly start the air compressor.

Note: Customers should not adjust the manufacturer's parameters of the air compressor at will. Adjusting parameters at will may cause the air compressor to fail to operate normally.

(7)After the air compressor is connected to the power supply, non-staff members should not operate it at will to prevent electric shock.

(8)About starting the air dryer: You need to turn on the air dryer 5 minutes in advance. There is a delay of about 3 minutes when the air dryer starts. (This operation includes a 4-IN-1 integrated air compressor’s air dryer and a separately connected air dryer)

(9)The air tank needs to be drained regularly, about once every 3-5 days. (This operation includes the air tank under the 4-IN-1 integrated air compressor and the separately connected air tank)

(10)After the new air compressor has been used for 500 hours, the controller will automatically remind you to perform maintenance. For specific maintenance operations, please refer to the information connected below: (The first maintenance time is: 500 hours, and each subsequent maintenance time is 2000-3000 hours)

https://www.oppaircompressor.com/news/how-to-maintain-screw-air-compressor/

When it’s time for maintenance, what kind of air compressor oil should I choose?

Customers can choose No. 46 synthetic or semi-synthetic air compressor oil. There is no restriction on the brand, customers can buy it locally, but it must be special oil for air compressors.

(11)Can the sleep time of the air compressor be customized? (Sleep means that when the air compressor terminal is not using air, the air compressor will automatically enter the idling state. The default manufacturer setting is 1200 seconds. When the air compressor enters the idling state, it will wait for 1200 seconds. If there is no air usage, the air compressor will automatically stop.)

Yes, it can be set between 300 seconds and 1200 seconds. OPPAIR default setting is 1200 seconds.

3. What are the normal stopping steps for a screw air compressor?

(1)Press the screen stop button

(2)Cut off the power

4. What is the password for the OPPAIR air compressor?

(1)User parameter password 0808, 9999

(2)Factory parameter password 2163, 8216, 0608

(Note: Factory parameters cannot be changed at will. If the air compressor cannot operate normally due to changing parameters by yourself, the manufacturer will not provide warranty. If you need to adjust a parameter, please contact us first. Modifications can be made under the guidance of our technical staff)

Post time: Dec-26-2023